ITP Studio Tools Software All Your Required Studio Measurement & Build Functions in One Software Package...

ITP Studio Tools Software Requires Only a Few Hours Training for Maximum Productivity...

ITP Studio Tools Software All the Features Required for Rapid Model & Prototype Production...

ITP Studio Tools Software All the Features Required for Rapid Model & Prototype Production...2

<

>

Expand a category below:

ITP Studio Tools Software

ITP Group's Studio Tools Software

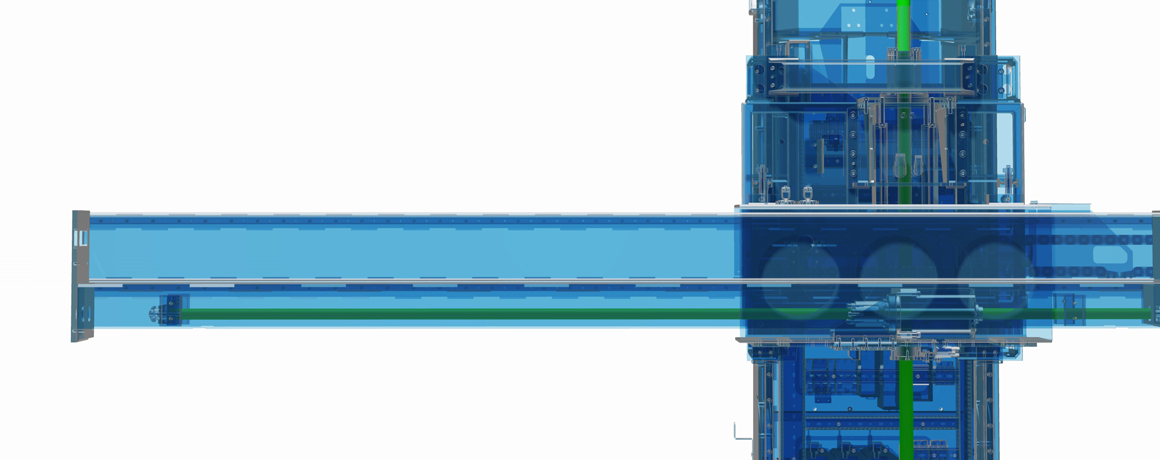

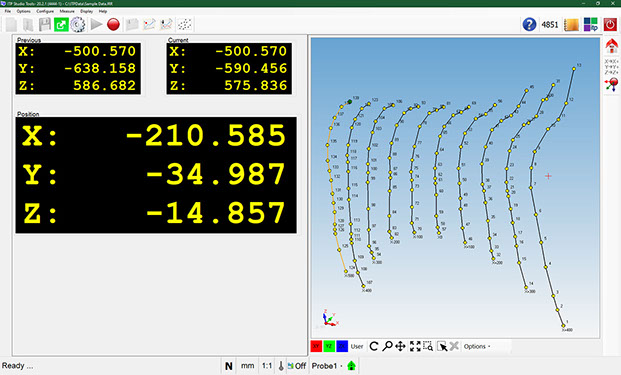

Our Studio Tools software solution is an easy-to-use Digital Read-Out (DRO) package for manual measurement, digitising and reverse digitising.

The software has been developed exclusively for studio use and combines all the required studio measurement and build functions into one package.

By listening to styling studio users ITP has created a package that gives the required studio functionality, whilst not overloading the users with a full inspection package (available if required) that would require 2-4 days training and regular usage.

Visit ITP's YouTube Channel to See a Demonstration of Studio Tools

Click Here

ITP Group Studio Tools requires only a few hours training, but offers all the features required for rapid model and prototype production.

For further information on ITP Group's Studio Tools Software, or to discuss a specific software requirement for your business, contact ITP Group telephone +44(0)1788 570357 or email: sales@itpgroup.co.uk

In House Software Team

ITP Group's in-house software team can create custom CMM software solutions to overcome small problems such as connectivity and compatibility, to creating complete turnkey solutions for specialist applications.

Our software team can re-code standard CMM software packages to increase functionality, or simplify applications. Alternatively, entire CMM software packages can be created for non-standard applications unique to specific organisations.

For further information on ITP Group's Custom Designed Software, or to discuss a specific software requirement for your business, contact ITP Group telephone +44(0)1788 570357 or email: sales@itpgroup.co.uk

ITP Studio Mill

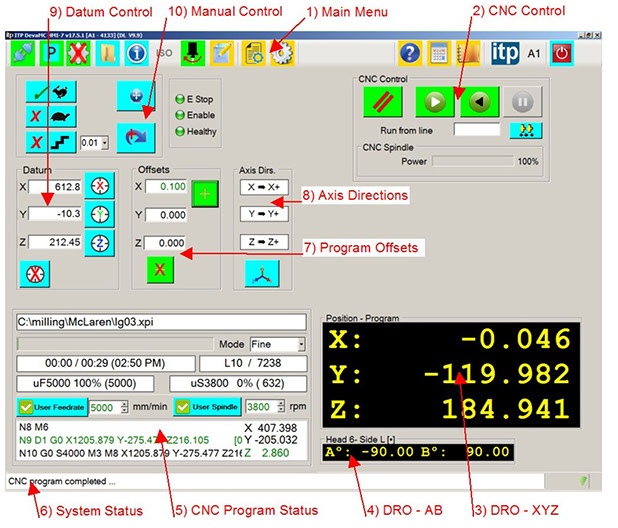

ITP Studio Mill is used to control the ITP range of milling systems.

Developed by ITP Group's team of software writers in direct response to feedback from existing studio users. ITP Studio Mills has unique features that are not available on standard milling systems.

The ITP Studio Mill software focuses on what studios actually require from a software package for full studio model production whilst excluding the complexity of standard milling software interfaces,

The system’s ease of use and compact design reduces training time to less than 1 day and alleviates mistakes.

Main Features :-

- User-friendly display with large colour coded icons for ease of use in studio. Icons disabled when not available, with balloon tooltips on all buttons and dialogs and integrated Help. Easy to use, normal initial training period just 2 hours

- Accepts CNC programs generated from most CAD CAM packages eg Work NC, PowerMill, Tebis, Unigraphics & Catia

- CNC programs are checked for errors, machine boundary infringement and entirety before execution.

- 3D joystick control with axis locks, reverse operation, normal mode, slow mode and micron step mode for exact positioning

- Joystick control of program run, pause, resume, datum set, XYZ offsets & feedrate override allowing control ‘at the model’

- Manual Control allowing spindle On / Off, XYZ jog, XYZ park & XYZ move

- XYZ Axis directions and assignments can be set as required eg +X +Y +Z ® -Z +Y –X to allow for optimum part orientation

- Datum set in X / Y / Z axis to input values

- Program XYZ offsets can be adjusted during program run to correct for misalignment

- Cycle Pause / Start controls with spindle motor off during Cycle Pause

- User feedrate & spindle speed overrides

- Programs can be started from a specified line to allow for part run of programs and recovery from collisions

- User selectable surface finish modes - Fine / Semi / Rough

- Program status display showing : - part run duration sliding scale, run duration and time left, current line and total lines, max and percentage feedrate, max and percentage spindle speed, previous / current / next line and distance to go

- Disable motors mode to allow manual datum setting

- Spindle load monitor to slow feedrate when model ‘over clayed’

- Spindle stall monitor to protect CNC machine and model

- XYZ axis program search facility to find program start position

- Spindle start and stop delays for smooth operation

- Create Drill Program option to create a drill program from a curve in IGES / Text point file

- Mirror / swap axis & skim program utilities

- 2 axis head option to allow cutter tip orientation during / between programs

- Remote feedrate control option to allow machine operation outside safety barrier

- Password operation protection option for open studio environment

Want to know more? Contact ITP Group Ltd for further information +44 (0)1788 570357

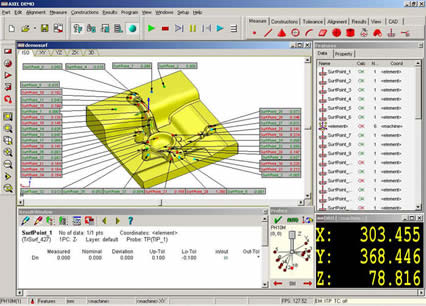

Axel Measurement Software

Axel Measurement Software for Windows provides a fully integrated measuring environment. All geometrical, surface and pipe measurements are made from within a uniform user interface. Axel CMM Software features a standard user operator interface throughout, possess identical icons with standard features as well as a standard initial screen presentation which can be changed or varied at the operator's convenience.

The Axel Measurement Software product range consists of the following applications:

Axel Lite CMM

Axel CNC CMM

Axel Offline Programming

Axel Surface CMM

Axel Pipe Wizard

Axel Foundation Software

Graphical Measurements on Coordinate Measuring Machines

Axel Foundation software is the main program for geometrical measurements. It also comprises the basic package for the entire range of Axel applications and other CMM software, and uses the latest and most innovative in CMM software engineering technology.

Axel Foundation CMM software is built around a unique user interface. From this initial point the user can access all the features of the program. Axel Foundation CMM Software has the capability to measure any type of shape including spheres, cones, cylinders, flat surfaces or a combination of them.

Axel Foundation Software Features:

- Geometrical measurement with options for CNC, CAD Surface Inspection & Pipe Measurement

- Feature storage & draw measured features

- CAD-like feature constructions, e.g. distance, intersection, translation, rotation & projection

- CAD import (IGES & DXF as standard)

- Multiple coordinate systems

- Extensive alignments with graphical representation in the Measure Window

- Full dimensional & geographical tolerancing

- Reverse engineering to CAD

- Multiple Measure Window part views with graphical zoom & rotate, solid or wireframe view

- Select features or CAD from graphic view

- DDE / file / serial data export to MS Excel & Lighthouse SPC

- Alter name of stored features to match drawing / client name

- Graphical results boxes in Measure Window & reports

- User configurable, fully featured text & Graphical Report Generator

- Export reports to MS Excel, HTML or PDF

For further information on any of ITP Group's CMM Software, or to request a full quotation, Contact ITP Group.

For a document outlining the Key Differences Between Axel Lite And Axel Foundation CMM software, or to find out about all of the Features And Benefits Of Axel Lite CMM software, please contact ITP Group

For further information on any of ITP Group's CMM Software, or to request a full quotation, Contact ITP Group.

Axel Offline Programming Software*

Axel Off-line Programming Software can be used in addition to the Axel CNC Visual Programming option outlined previously. It allows complete CNC programs to be created and tested off-line from a CAD model.

Axel Off-line Programming CMM Software Features:

- Standard Microsoft joystick or on screen joypad used to interface with CAD model for measured points & learn positions

- Placement of CAD model within CMM envelope

- Extraction of measured Geometric & Surface features from CAD model

- Direct measurement of CAD model via joystick control

- Control of CNC speeds, back-offs, margins & safety positions

- Full control of program macro parameters to cope with intricate parts

- Renishaw probe-head, probe & styli model definitions

- Selection of defined PH10 probe positions

- Easy insertion of extra learn points to avoid collisions with fixtures / clamps etc

For a video containing a complete training overview, contact ITP Group.

*Axel Foundation required in addition to this module

For a document outlining the Key Differences Between Axel Lite And Axel Foundation CMM software, or to find out about all of the Features And Benefits Of Axel Lite CMM software, please contact ITP Group

For further information on any of ITP Group's CMM Software, or to request a full quotation, Contact ITP Group.

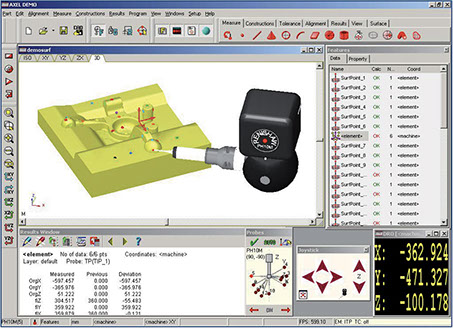

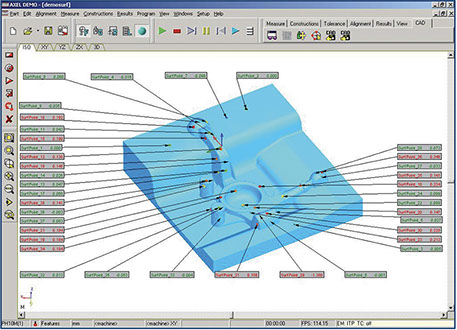

Axel Surface Inspection Software*

Surface Inspection Software for CAD Generated Parts

Axel Surface Inspection CMM software adds surface inspection features to the standard Axel Foundation program, thus providing a truly integrated geometrical and surface measuring environment.

Axel Surface Inspection CMM software allows the user to measure complex shapes on manual CMMs, Measuring Arms or CNC CMMs. Results are then made available in numerical and graphical formats.

Axel Surface Inspection CMM Software Features:

- Part inspected against nominal CAD data

- Parametric / BSpline / Trimmed surface inspection

- Part alignment with 3D best-fit method, multi-entity or Reference Point System

- Surface point & surface edge inspection

- Graphical representation of surface errors

- Label / vector / colour coded representation of surface errors

- Adjustable search range & error magnification

- Rendered or wire-frame graphical views

- Mouse rotation / pan & zoom / view grid / adjustable shadows & lighting

- CAD feature interrogation & capture / layer & CAD entity control

- Metal thickness compensation

- Interfaces available to various CAD formats - DXF / IGES / CATIA v4 & v5 / ProEngineer / STEP / VDA

*Axel Foundation required in addition to this module

For further information on any of ITP Group's CMM Software, or to request a full quotation, Contact ITP Group.

For a document outlining the Key Differences Between Axel Lite And Axel Foundation CMM software, or to find out about all of the Features And Benefits Of Axel Lite CMM software, please contact ITP Group

For further information on any of ITP Group's CMM Software, or to request a full quotation, Contact ITP Group.

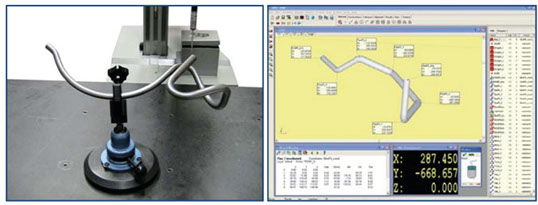

Axel Manipulated Tube & Surface*

ITP Group have often been asked to outline the benefits of ITP Group Horizontal Arm coordinate measuring machines compared to Flexible Arm CMM Systems for the measurement of manipulated tube, pipe, wire or hose. At first glance a Flexible Arm CMM may seem a worthy alternative – they appear simple to use with non-contact technology. However, if it doesn’t measure accurately, and only does part of the job, are you sure that a Flexible Arm CMM is the right system for you?

ITP Group have developed software and hardware driven by our client requirements, and not only can ITP Group Horizontal Arm coordinate measuring machines inspect tube, wire & hose assemblies more accurately than Flexible Arm Systems, they can then go on to inspect the individual brackets, end fittings, ‘T’ sections and also tube fixtures.

ITP Studio Tools | ITP Studio Mill | Axel Measurement Software