ITP GROUP OF COMPANIES

CLIENTS

- Aerotech Tubes

- Aston Martin

- Bajaj Auto

- Beijing Space Authority

- Bentley Motors

- British Nuclear Fuels

- CEMEX

- Chang An Motors

- Concept Group International

- Coventry University

- Eaton Corporation

- EDAG

- Encocam

- Envisage Group

- Futura Design

- GE Energy

- General Motors Shanghai

- Gordon Murray Design

- Holden Special Vehicles

- HPL Group

- Hyundai Motor Company

- Jaguar Cars

- KIA Motors

- KISKA Design

- Mercedes GP

- McLaren Automotive

- Morgan Motor Company

- MV Augusta

- Nissan Motor Manufacturing

- Peugeot Motor Company

- PFW Aerospace

- Renault Trucks

- Royal Air Force (RAF)

- Rolls Royce Aero Engines

- SAIC

- SEAT

- Sigma Precision

- STADCO

- Tata Automotive India

- Tata Automotive UK

- TATA Steel

- Thales Group

- Toyota Motor Corporation

- Triumph Motorcycles

- Visioneering

- Visteon Autopal

- VW Audi

- Williams Formula One

See a Selection of the Global Companies that ITP Group Supply

Click Here

Company History

ITP Group have been providing cost effective solutions for measurement and styling applications since 1978, and have supplied over 3000 machines in 30 countries over 6 continents.

All ITP Group productions and software are manufactured and developed in-house and supported by our global team of mobile service engineers. ITP Sales Ltd is the ultimate holding company, which manufactures, markets and sells its complete range of measuring, styling and special purpose inspection machinery.

ITP CMM's Ltd is responsible for the installation, service and calibration of all ITP Group machinery sold worldwide. We also retrofit and upgrade most third party coordinate measuring machines. ITP Asia Ltd is our Australasian base from which we have the ability to offer all of the ITP manufactured products to the Far East and Australasian market place. If you have a specific question, require extra information regarding the ITP Group's product line, or cannot find what you're looking for on our website, Contact ITP Group.

British Made

ITP, a unique British manufacturing company, having manufactured some of the largest co-ordinate measuring machines in the world to the top names in the Automotive and Aerospace Industry.

Being a "true" manufacturing company, ITP are able to satisfy specific requirements for special systems and have provided to such prestigious companies as:

Aston Martin Lagonda, Beijing Space Corporation, Bentley, BNFL, CEMEX, and Volkswagen Audi.

We are proud of our British Heritage and continue to fly the flag for British manufacturing throughout the World.

ITP | Australasia

ITP opened their offices in Asia 14 years ago, thus giving them a presence in the fast paced Australasian market place. From our Australasian base we have the ability to offer all of the ITP manufactured products to the Far East and Australasian market place.

If you have a specific question, require extra information regarding the ITP Groups product line, or cannot find what you're looking for on our website, contact ITP Group.

ITP | Large Machines

ITP group have had considerable success in the design and manufacture of machines and systems that do not come into the categories covered by standard machines, potentially due to the size requirements and multi axis, where normally a standard solution to the requirement would not be available.

ITP have successfully manufactured CNC machines with thirteen axis of movement and axis lengths in excess of 50 meters to date....what's the next challenge? Why not pick up the phone and talk to us about how we can help you achieve your requirements.

ITP | 1980 The Formative Years

During the 1980s ITP Group carved out a niche for manufacturing styling studio machinery and coordinate measuring machines for both the automotive and aerospace sectors. It gained a competitive edge by guaranteeing that the entire process was designed, developed and manufactured in-house. That helped ITP build an impressive client base comprising many of the world’s top automotive companies.

During the 1980s, ITP Group also gained traction in sectors such as circuit production. ITP supplied measuring machines for PCB manufacturer, Flexible Technology and Isle of Wight based business, Polyflex Circuits.

ITP | 1990 CEMEX Project Creates The Mould for Long-Term Partnerships

As ITP Group entered the nineties, an order from globally renowned company CEMEX allowed the company to enter a new field of opportunity. CEMEX supplies concrete sleepers and crossing bearers to the rail industry and sought assistance in improving efficiency.

ITP designed and built a bespoke CNC drilling machine which revolutionised CEMEX’s railway bearers’ production process. ITP Group went on to deliver machines which accurately positioned pandrols to be cast directly into the bearer mould.

The companies have continued working in collaboration on projects including Crossrail and the upgrade to Paddington Station.

ITP | 2000 Launches Next Stage Growth With Beijing Space

In 2004, Beijing Space approached ITP Group to design a machine that would be capable of machining and inspecting satellites before launch.

The ITP Group team designed and built a steel fabricated horizontal arm structure to machine the location pads and, in addition, drill all the location holes required on the satellite to accommodate the solar panels.

Within five years, the ITP Group bespoke designed machine helped boost the number of annual satellite launches from 5 to 35. That relationship has continued to evolve and since 2005, ITP Group has supplied a further five machines.

ITP | 2010 Achieves Greater Heights With McLaren Automotive

Since 2010, ITP Group has set new standards in design and innovation. Case in point is the design and manufacture of a specialist milling system used by McLaren on its new coupe model.

Over the years, ITP has supplied machines and complete studios to assist in the build of McLaren’s legendary road cars.

The current studio is equipped with a twin column HA400 CNC milling machine, with full 5 axis CNC operation, which features two tracks and two three-tonne hydraulic tables. The machine allows McLaren to lift the model more than a metre above the track.

ITP | 2020 Celebrates 40 Years & Launches it's StudioStyleTM HA180 Clay Milling Machine

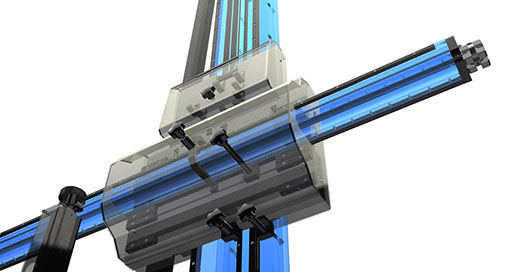

2020, ITP Group unveiled another game-changing product, the StudioStyleTM HA180. This horizontal arm 3D modelling machine has been specifically designed around the requirements of many of the world’s leading automotive design and styling studios.

A completely new concept, the machine doesn’t use any traditional rotating bearings compared to the 62 in previous machines. It’s much easier to use, requires less frequent servicing and has been designed to be extremely rigid and light in its operation. The new system incorporates a high-precision recirculating crossed roller design with the very latest locks and fine drive technology.

Want to know more about the StudioStyleTM HA180 horizontal arm 3D modelling machine? Talk with one of our team on +44(0) 1788 570 357 or why not email us at sales@itpgroup.co.uk